Can render solid, touchable versions of drug, virus molecules,

architectural models, and artificial limbs….

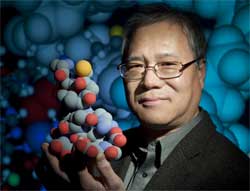

KINGSTON, R.I. – February 28, 2011 – Professor Bongsup Cho sat at his desk discussing a new 3-dimensional printer that will soon be a part of the University of Rhode Island’s College of Pharmacy.

As he explained how the printer will make touchable, textural and colorful models of drug molecules, cancer molecules or bacteria, a visitor to his office was incredulous. “Will the printer make 3D paper images in an origami-like fashion?” Cho was asked. “Will it make these images out of cardboard?”

Then Cho, a biomedical scientist who specializes in DNA damage and mutations as they relate to the development of cancer, pulled out a 3D “print” of a drug molecule. It was 8 inches long, 6 inches high, weighed about 2-and-a-half pounds and was colored gray, red, purple and yellow. It took about seven hours to print a model of this size. Smaller models can take as little as 30 minutes to print.

That molecule model in Cho’s office is just the beginning of a new way for students to learn about drug effects on diseases, drug interactions and the genesis of diseases from mutating genes. For years, engineers and designers have been using 3D printers to make prototype models. Cho said the biomedical science community is now catching up. He said affordable prices and the addition of brilliant colors to the models helped build the momentum.

A $123,600 grant from the Champlin Foundations has made it possible for the College of Pharmacy to purchase the 3D printer system manufactured by Z Corporation of Burlington, Mass. Cho is working with co-investigators Roy Bergstrom, lead information technologist in URI’s Media and Technology Services, and Marian Goldsmith, professor and chair of biological sciences.

In addition to the 3D printer, the University will purchase five animation workstations, animation and visualization software and other accessories through the grant.

The additional equipment will allow the College to establish a new 3D Center for Biomedical Sciences at URI in the $75 million pharmacy building now under construction.

“Establishing the center will place URI among a select few leading higher education institutions using such cutting-edge technologies in their curricula,” Cho said.

A 2003 Champlin Foundations grant to the College of Pharmacy led to the creation of an animation laboratory at the College and the creation of close to two-dozen animation videos that have been used heavily in pharmacy classes and recorded more than 700,000 views around the world. The You Tube site, https://www.youtube.com/user/URIanimation#p/u, has had more visitors than any other at the University, Cho said.

That’s because the videos give clear, understandable presentations of biochemical reactions and molecular and biological processes that are difficult to absorb when instructors use only two-dimensional paper diagrams. The videos present moving, dynamic interactions on topics such as how drugs like the antidepressant Prozac, chemotherapy drugs Gleevec and Cisplatin, and aspirin work, as well as depicting DNA damage and protection and diuretic action in the kidney.

Now, however, with the new animation workstations and software, students will be able to manipulate molecules and proteins to view them from different angles and see how medications bind to them. They will then be able to produce physical models using the 3D printer. The new computers and software will allow users to work without cumbersome 3D glasses.

“Flat diagrams of chemical/biological and physiological actions have always been a less than optimum way to teach students,” Cho said. “Now, we will not only have the ability to look at such phenomena on a computer, we will be able to produce physical models that students can touch, look into and physically examine how molecules interact. Our students deserve the best equipment.”

According to Z Corporation, the material used by ZPrinters to create physical models is a composite resin powder, similar to the material used in plaster drywall. The models are built one .0004-inch layer at a time. The process uses a binder to solidify the powder. HP printer heads apply the binder and color, in the case of color models. The process is called additive manufacturing.

“Z Corporation is pleased be part of the URI’s effort in the introduction of 3D printing into their curriculum,” said Ed DeArias, the company’s vice president of global sales and service. “Building full color, physical 3D models has proven to be a valuable way for educators to engage students, enhance learning and encourage advancement.”

Cho said the 3D animation/printing technologies will benefit more than 1,000 students annually in introductory and advanced biomedical science courses and give students in pharmacy, biology, chemistry, film media, computer science, engineering, physical therapy and other programs opportunities to develop and apply 3D animation skills to enhance scientific understanding. The center will also be open to students in kindergarten through grade 12 through URI’s Science and Math Investigative Learning Experience (SMILE), an after-school program serving 240 public school students across the state annually.

“Young students and our own here at the University are helped tremendously by the wow factor,” Cho said. “This is a great way to help them grasp complex molecular and cellular processes. Sometimes, there is nothing like texture and feeling. We will be able to examine these processes in the center from start to finish. The equipment is not just for looking at biomedical processes. It can be used in creating sculptures, architectural models and prosthetic limbs, as well as in engineering and environmental science classes.”

Grateful for the Champlin Foundations’ generosity, Cho said he views this as a teaching grant. “I have a passion for using new technology to teach in new ways. I am sure the Champlin people were impressed with our continuing animation work and that’s why they agreed to further the University’s development in this area.”

Media Contact: Dave Lavallee, 401-874-5862