Electronic waste (e-waste) is a growing concern in the world, as the number of electronics used in everyday life continues to increase while the lifespan of these electronics continues to shrink.

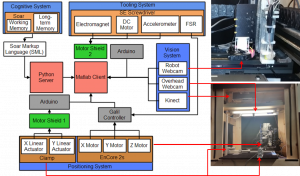

Efficient methods that can handle e-waste in an automated non-destructive fashion have not been developed. Screws are a common fastener used on electronic products, such as laptops, and must be removed during nondestructive methods. In this project, we focused on using the cognitive architecture Soar to facilitate the disassembly sequence of removing these screws from the back of laptops. A system equipped with several cameras and a custom, sensor-equipped screwdriver was developed that can accommodate laptops of various sizes. A screw removal procedure was developed that can automatically identity a screw, line up a screw for removal, and remove the screw. Using Soar, the system is able to differentiate between different models of laptops and store the locations of screws for these models leading to an improvement of the disassembly time when the same laptop model is used. Current efforts are focusing on using AI techniques to identify screw locations and types.

References:

- DiFilippo and M. Jouaneh, “Characterization of Different Microsoft Kinect Sensor Models”, IEEE Sensors Journal, No. 8, pp. 4554-4564, 2015.

- DiFilippo, and M. Jouaneh. “A System Combining Force and Vision Sensing for Automated Screw Removal on Laptops.” IEEE Transactions on Automation Science and Engineering, Vol. 15, No. 2, pp. 887-895, 2018.

- DiFilippo, and M. Jouaneh. “Using the Soar Cognitive Architecture to Remove Screws from Different Laptop Models.” IEEE Transactions on Automation Science and Engineering, Vol. 16, No. 2, pp. 767-779, 2019.