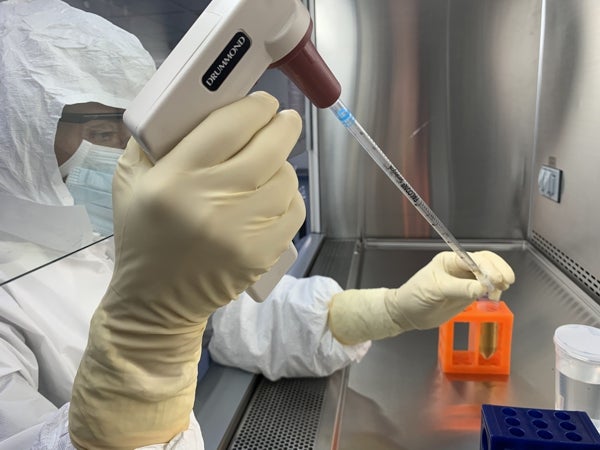

This course is designed for biopharmaceutical manufacturers to ensure that their employees, who are working in upstream processing, have clear understandings of and technical acumen for aseptic cell culture and scale up. Lectures and hands-on laboratories prepare participants to work effectively in upstream bioprocessing suites which includes maintenance and monitoring of aseptic environments while culturing mammalian cells.

Objectives

- Gain knowledge in methodologies and principles that underlie mammalian cell culture and aseptic upstream processing.

- Perform hands-on techniques for growing and maintaining anchorage dependent and suspension cell lines.

- Understand critical parameters involved in aseptic mammalian cell culture within various cell culture vessels including 2 L bioreactors.

- Understand and integrate cell culture methodologies and techniques with performance indicators in order to optimize individual proficiencies.

Who should attend this course?

Individuals working in the Biomanufacturing industry including roles such as Upstream Technician, Quality Assurance, Quality Control, Bioprocess Engineers

Delivery

In-person lectures and hands on activities in a simulated GMP facility.

- Duration: 1 Day

- Time: 8:00am to 4:00pm

- Location: Kingston, RI

- Max Number of Participants: 15

Instructors

Content Outline

Lecture

- Brief introduction to pharmaceuticals and biopharmaceuticals

- FDA regulations

- From gene modification to working cell bank

- The clean room environment

- Critical process parameters for cell growth and protein production

- Proper aseptic technique

- Thawing and plating cells

- Aliquoting samples for cell count and viability

- Environmental monitoring within the ISO 5 BSC (touch plates)

- Cell counting and determining cell viability

Lab Exercises

- Gowning into a clean room

- Proper Aseptic technique

- Thawing and plating cells

- Aliquoting samples for cell count and viability

- Environmental monitoring within the ISO 5 BSC (touch plates) – Results will be sent by e-mail to students

- Cell counting and determining cell viability