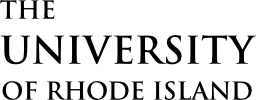

When properly sited, designed, installed, and maintained, onsite wastewater treatment systems (also called septic systems) are often the best choice for wastewater treatment in many areas, from public health, environmental, and economic standpoints. Onsite wastewater treatment allows water used in homes and businesses to be treated and recycled to replenish local groundwater supplies. This benefit of onsite treatment is not realized with municipal wastewater treatment, which discharges partially treated wastewater directly to rivers and coastal waters, sending wastewater either further downstream or out of the watershed entirely, and returning none to the landscape to replenish groundwater aquifers. This loss of groundwater recharge reduces the amount of groundwater available for drinking water wells. In coastal areas, depletion of ground water resources can lead to salt-water intrusion and loss of potable freshwater supplies. Because groundwater is the main source of flow to streams during dry weather, loss of recharge can also lower streamflow to levels that can no longer support healthy aquatic life.

The most common type of onsite wastewater treatment system in the U.S. is a “conventional” or gravity-fed system, consisting of a septic tank, distribution box and drainfield. However, some areas – especially ones sensitive to nutrients and pathogens – require specially engineered “advanced” systems that remove more contaminants before dispersing wastewater to the soil. Regardless of the type of system you have, it requires periodic maintenance to continue to perform well over time.

Video Overview Describing Septic System Function and Maintenance

Explore Septic System Function and Best Practices with this Interactive Tool

Visit “How a Septic System Works” (also available in Spanish) created by GBRA and the Texas A&M Extension Program. Note this is an external site and consists of an interactive clickable diagram describing how systems work, and how household use can help or hinder their performance.

Understanding Conventional Onsite Wastewater Treatment Systems

The term ‘conventional’ refers to the standard gravity flow design, which consists of a septic tank, a distribution box, and a drainfield. Conventional systems function very well on sites with few constraints as they rely on the native soils to treat bacteria, dilute other waste that is not treated, such as nitrogen, and disperse wastewater generated in the home or business.

For low-density sites with sufficient space for setbacks and dilution, good soil conditions, and deep water table, conventional systems are the least expensive to build and maintain, and are remarkably efficient. Reliance on native soils for treatment of wastewater can be a severe limitation in areas where soil conditions are not ideal for the infiltration and treatment of wastewater, or where the land area available is insufficient to handle large water loads. Primary treatment (settling of solids and fats, oils, and greases) of wastewater that takes place in an onsite system is the exact same step found in municipal sewer treatment plants, but done on a much smaller scale.

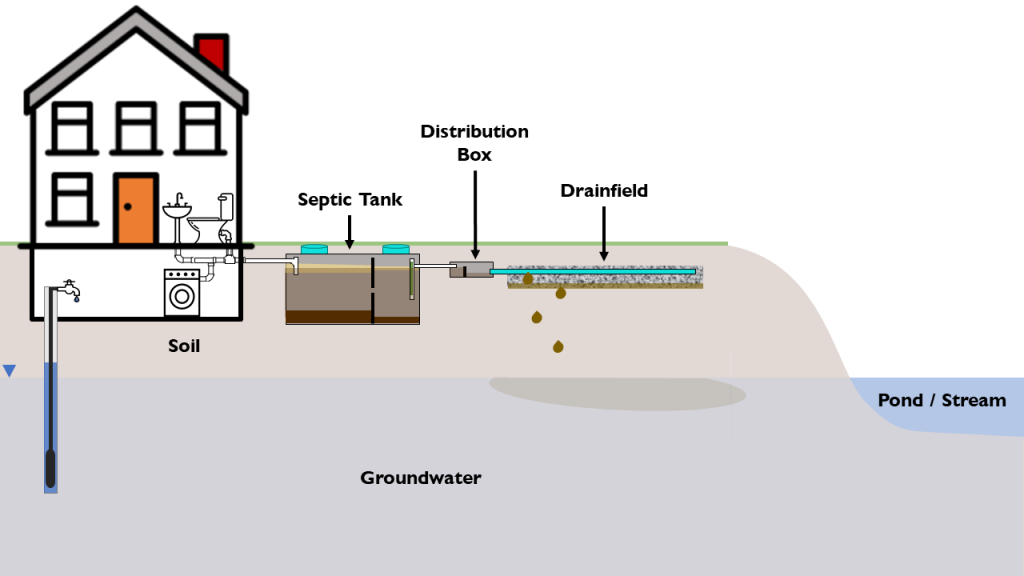

The Septic Tank

The main purpose of the septic tank is to temporarily retain and store wastewater to allow solids, and fats, oils, and greases (FOG) to separate and get broken down by anaerobic bacteria (bacteria that survive in areas with little or no oxygen) before it flows into the drainfield. The tank is generally designed to provide a 2-day retention time for wastewater settling to occur. In properly functioning septic tanks, up to 80% of the solids are broken down into gases and liquids. Modern tanks are also equipped with effluent filters, which are designed to keep small floating solids in the tank and out of other septic system components (where they can cause problems).

How a two compartment Septic Tank works

After you flush waste or rinse waste down a drain, it travels down a sewage pipe into the septic tank. In the septic tank, the wastewater will settle and the non-liquid components divide into two parts: heavy solids sink to the bottom forming a layer of ‘sludge’, while light solids and FOG form a floating ‘scum layer’. The wastewater that does not contain any of these two components will flow from the first to the second compartment through a gap in the baffle to further settle before it enters the distribution box. During this, anaerobic bacteria will break down some of the wastewater into gases and liquids. Even though this wastewater was partially treated by anaerobic bacteria (in the septic tank), it still contains many pollutants and disease-causing microbes.

The minimum tank size for a single-family home is typically 1,000 gallons. Various types of tanks are approved for use in our area – tanks can vary in size, configuration, and material. The most common type of septic tanks are constructed from concrete, though fiberglass tanks are regularly used on lots with limited access to heavy equipment. Tanks that were installed prior to current state standards could vary from steel drums to concrete cylinders, and typically only have a single compartment. The tank shown here is a modern typical two-compartment tank, split by a divider called a baffle; the first compartment contains 2/3 of the tank volume, the second contains 1/3. Two compartment tanks are typically larger than single-compartment tanks, with a capacity of 1,500 gallons. They also ensure a more thorough separation of FOG and sludge and provide more protection to the drainfield. Because of this, most northeastern states in the U.S. require a two-compartment tank for new construction, repairs and replacements.

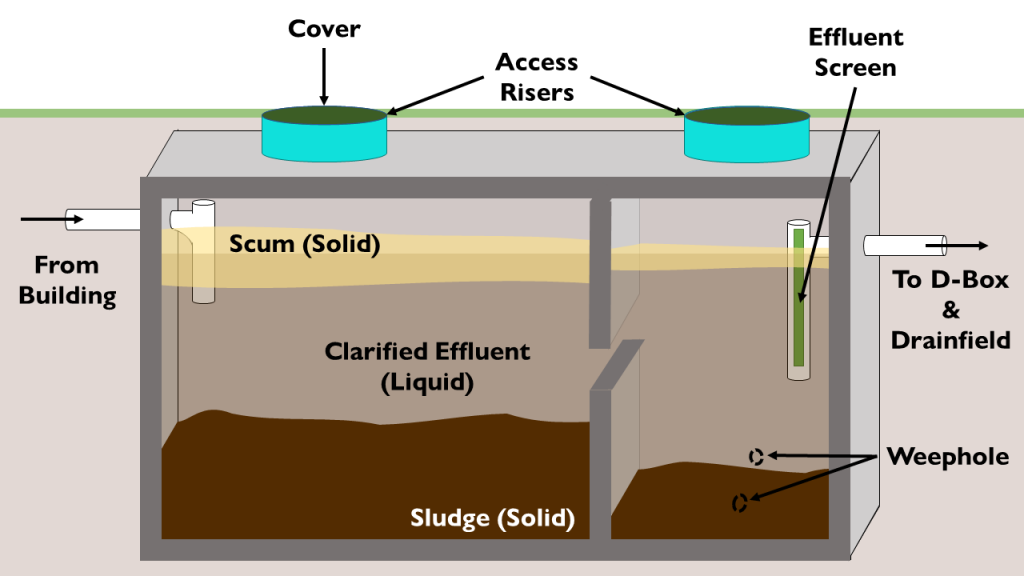

The Distribution Box

The distribution box lies between the septic tank and the drainfield, and serves to evenly distribute the wastewater evenly amongst the drainfield lines. Ensuring even distribution of the wastewater is crucial in maintaining the longevity of the drainfield. If only a small portion of the drainfield is actually used due to poor distribution, localized saturation of a drainfield line may occur. Organic matter and solids may build up faster than they are broken down by soil microbes clogging soil pores, causing the drainfield to fail prematurely. A typical D-box is pre-cast with multiple holes, as seen here, to allow for use in various system configurations. For example, the drainfield lines may be located in various positions relative to the incoming pipe; on either side of the D-box, both on one side, etc. The D-box shown here has three pipes; one delivering wastewater from the primary treatment tank, and two to distribute effluent to the two drainfield lines or trenches.

The Drainfield

Drainfields serve to disperse wastewater to the soil environment, where pathogens are expected to be trapped and killed by beneficial soil microorganisms. The size of the drainfield will depend on the anticipated volume of water to be produced in the home and the soil conditions at the site. In Rhode Island, the drainfield may be one of three basic types: (i) Trenches, (ii) Concrete Leaching Chambers, or (iii) proprietary alternatives. In situations where required separation to groundwater cannot be met, modifications to the conventional drainfield, such as mounding, filling or above-ground components may be approved for use.

Types of Drainfields

Trench Drainfield

A trench type drainfield consists of two or more parallel trenches containing a perforated PVC pipe surrounded by washed crushed stone. The crushed stone is covered by geotextile fabric to ensure that fine soil particles do not fill voids between the stones, and native soil is used to fill the trench to the ground surface. Wastewater flows from the distribution box into the drainfield PVC pipes, to the crushed stone, and then to the soil environment.

Concrete Leaching Chambers

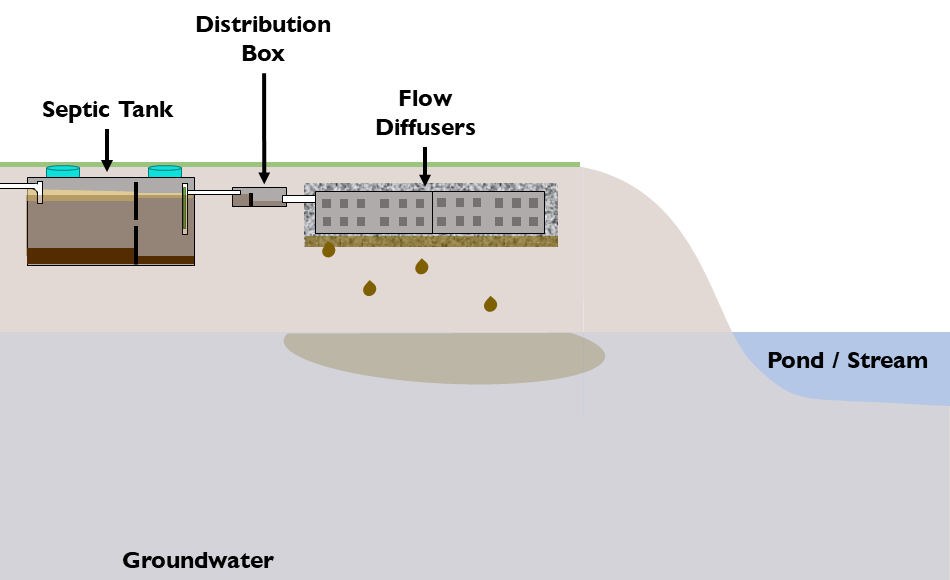

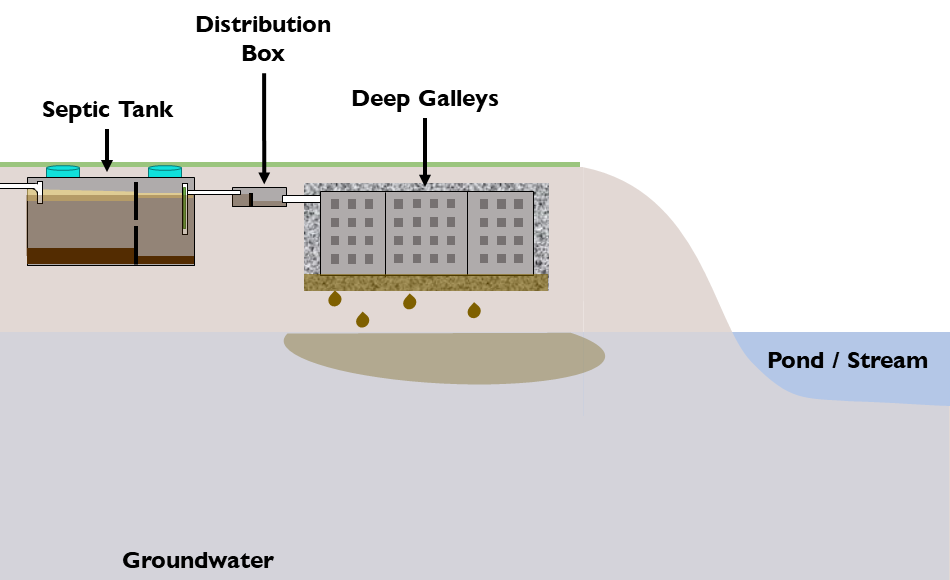

Leaching chambers are bottomless, perforated, concrete boxes surrounded by crushed stone on the sides and bottom. These are generally installed in a series of three or more units, depending on the anticipated volume of wastewater. Liquid effluent flows from the septic tank into the chamber, where it seeps out the side walls and bottom. Flow diffusers and galleys are the two types of leaching chambers commonly used in the state.

Shallow Flow Diffusers

Flow diffusers are shallow units, typically installed about one to two feet below the ground surface and are 8’x4’x2’ in size.

Deep Galleys

Deep galleys are 4’x4’x4’ units, and may be installed as deep as 10 feet below ground, depending on the site characteristics and system design

Advanced Treatment Systems

Advanced treatment systems differ from conventional systems in a number of ways, the primary difference being that they further treat the wastewater before it is dispersed to the soil environment. Advanced treatment systems incorporate carefully designed treatment steps, and create conditions to facilitate a consistently high degree of treatment. Many advanced treatment systems control flow through the system using pumps and timers to avoid overloading the treatment and final dispersal components during periods of high water usage, or “peak flow” conditions, which could occur during a morning rush of activity or when many guests are in the home.

The treatment provided by the advanced treatment system serves to further reduce the “strength” of the wastewater, or the solids, fats, oils, and greases (FOG) that are suspended in the effluent. This step may also contribute to reductions in pathogens and/or nutrients in the wastewater depending on the design and configuration of the system.

Systems that function to reduce nitrogen generally recirculate the effluent back to the septic tank or to a separate recirculation step where raw effluent and treated effluent are mixed, creating conditions that facilitate the removal of nitrogen by beneficial bacteria.

Advanced treatment systems are designed as a “treatment train,” or a logical sequence of treatment components to achieve a certain level of treatment, which may be specified by local, state, or regional governing agencies. In Rhode Island, the Department of Environmental Management (DEM), Coastal Resources Management Council (CRMC), and town governments may all have jurisdiction over a given area of land, and may impose differing regulations regarding wastewater treatment.

Technologies are initially chosen based on the level of treatment that is required, as not all technologies will effectively achieve nutrient and/or pathogen reduction. Treatment technologies achieve the best results when receiving wastewater with certain chemical and microbiological characteristics, and so the components are chosen and paired up with this in mind. Site constraints may also dictate the potential use of some technologies. For instance on small lots with existing homes and failed septic systems, the advanced treatment technologies with the smallest footprints are most commonly used as replacement systems. Advanced treatment systems generally require annual or semi-annual maintenance activities in order to function properly; these maintenance activities should be performed by a trained and qualified service provider.