- Assistant Professor, Mechanical, Industrial & Systems Engineering

- Joined College of Engineering faculty in 2020

Which research topics are you most interested in?

I am interested in microfluidics, also known as lab-on-a-chip technology, with a focus on applications in environmental monitoring and biomedicine.

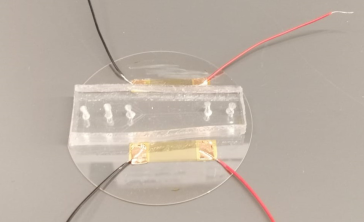

Since 2020, our lab has been working on implementing acoustofluidics to control various microparticles, with sizes ranging from one micron to a few hundred microns in miniaturized devices. With this technology, we could achieve rapid fluid actuation, contact-free and non-invasive particle manipulation without complex chip design and fabrication.

We’re collaborating with experts in oceanography and machine learning to explore effective, smart and continuous approaches to separate and identify ocean pollutants, including heavy metals, plastic waste and harmful chemicals. Our research could help scientists learn about trends in environmental pollution.

I’m also interested in learning if blood flow patterns, or the underlying hemorheological parameters, can improve the diagnosis and prognosis of heart diseases. By creating a vessel-on-a-chip to replace the animal models, metrics such as the flexibility of the blood vessels and viscosity of the blood can be precisely controlled. This can provide new knowledge of cardiovascular disease, which is the leading cause of death.

What technology do you use for your research?

We have a CADworks3D µMicrofluidics 3D printer in the lab, which has a resolution of 25 microns. It not only prints the enclosed transparent chips for direct microfluidic use, but it also prints the master molds for creating flexible and biocompatible microfluidic chips. It cost approximately $10,000.

We have two complete setups for acoustofluidic applications, one for bulk acoustic wave manipulation based on bubbles trapped in the microchannels, and another for surface acoustic wave manipulation. That equipment cost about $12,000.

Who are you collaborating with on research?

I’m collaborating with researchers at URI and other universities who specialize in chemical, biological, computer and ocean engineering. I hope to connect with faculty members in other departments at URI and other universities. I would also like to establish connections with industrial leaders and small businesses. Microfluidics is a highly interdisciplinary field, so collaboration is extremely important.

What do you like most about working at URI?

Since joining the faculty in 2020, I have seen some exciting research projects in the College of Engineering. Current and potential collaborations with other faculty make me feel confident that I made the right career decision to come to Rhode Island.

The facilities here are also conducive for interdisciplinary research that requires microfabrication, nanotechnology and bioengineering.

I’ve also enjoyed speaking with the students at URI, who are always energetic and mindful.

What do you enjoy doing when you’re not working?

I like trying new things. Recently, I’ve been learning fishing, crabbing and woodworking. I also enjoy hiking.