Our research group utilizes interdisciplinary approaches to produce novel soft materials that respond to their local environment or that possess novel functionality. We combine fundamental knowledge in the fields of chemical engineering, materials science, and physics to understand and manipulate the structure and dynamics of a wide range of soft matter building blocks, including polymers, colloids, and liquid droplets. Some of our current projects are described below.

Current Projects

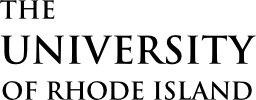

Biomimetic Soft Matter

We aim to design fully synthetic systems that replicate structures and functionality of biological systems. Current approaches include generating polymer-linked emulsions using novel triblock copolymers and mechanical capsules spontaneously nucleated through liquid-liquid phase separation.

Block copolymer synthesis performed in collaboration with Dr. Benjamin McDonald (Brown University, Department of Chemistry)

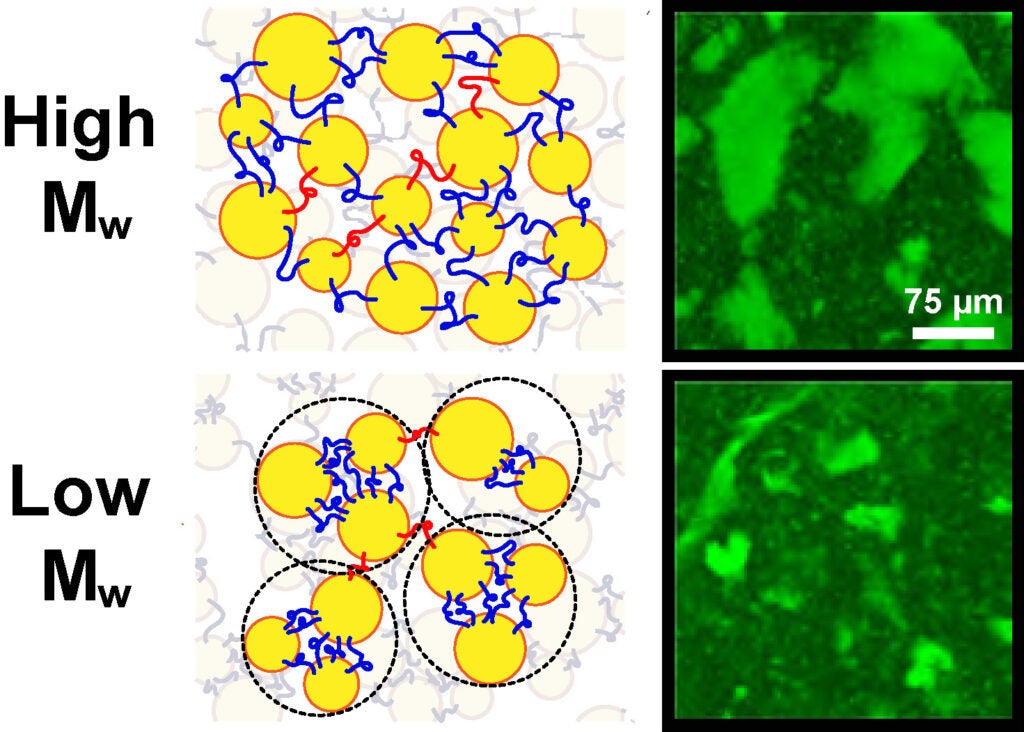

Physics of the Yield Transition

We investigate how soft materials transition from solid-like to liquid-like behaviors under stress to better understand bioengineering scaffolds and processing conditions of complex fluids. Our approach relies on the development of novel rheological protocols that isolate yielding in the presence of structural rearrangements and modeling the kinetics by which structural elements break and reform.

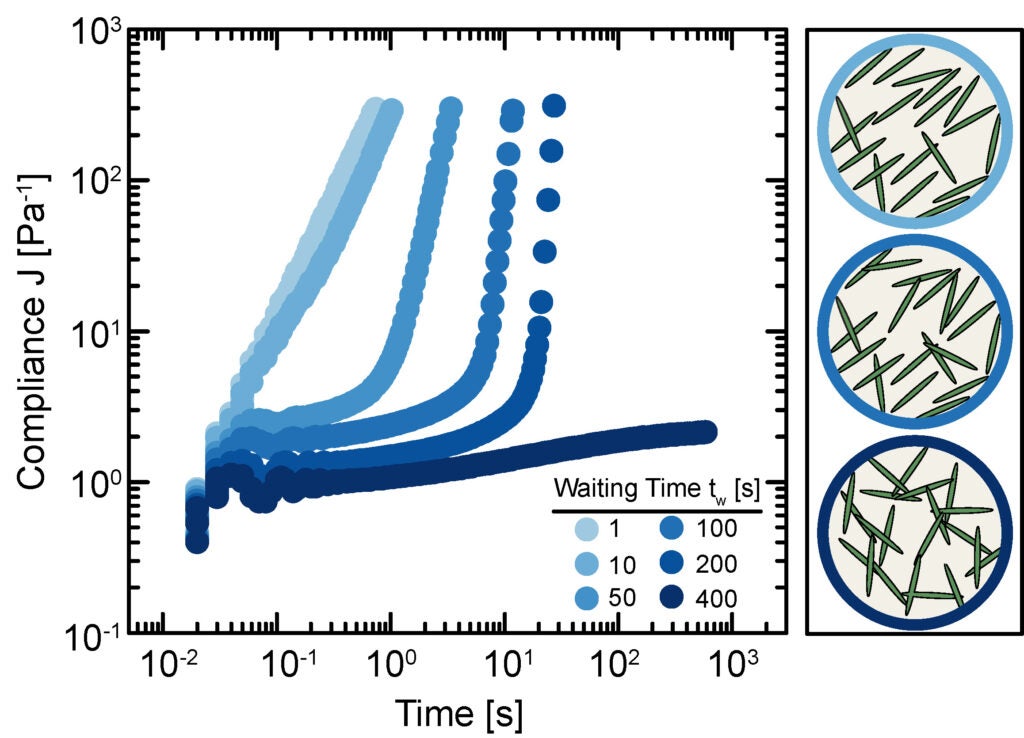

Design of Complex Fluid Inks for Additive Manufacturing

Additive manufacturing (also known as 3D printing) can produce physical objects with a high degree of spatial resolution and on time scales orders of magnitude faster and cheaper than traditional manufacturing techniques. We identify the rheological properties of complex fluids necessary to facilitate direct-ink-writing (DIW) to improve formulation development and composition.

Stability of Polymers in Natural Gas Environments

Commercial and residential natural gas is delivered through an aging network of pipes, mostly cast iron, which are prohibitively expensive to replace. Instead, polymer liners can remediate the pipelines much more easily and cheaply. We quantify the stability of various polymers under exposure to natural gas environments to assess their performance over the next decades or century.

Project in collaboration with Dr. Edith Mathiowitz (Brown University) and Dr. Vikas Srivastava (Brown University)

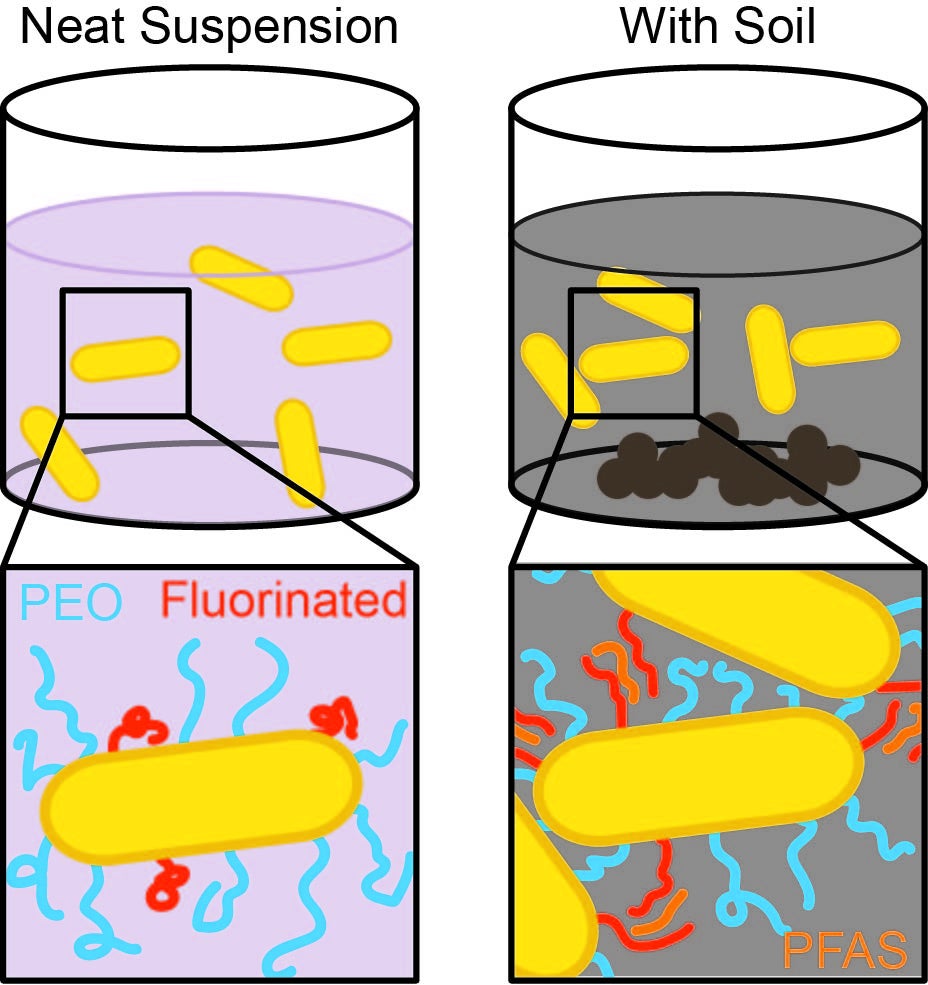

Environmental Interfaces and Nanotechnology

Our group is interested a number of questions regarding how the environment and microbes interact with soft matter interfaces. Specific thrusts include the development of polymer-grafted nanoparticle-based sensors to detect environmental contaminants, the characterization of biogenically produced inorganic nanoparticles, and the production of hierarchically structured anodes for benthic fuel cells.

Projects primarily in collaboration with Dr. Vinka Craver (URI, Department of Civil and Environmental Engineering) and Dr. Irene Andreu (URI, Department of Chemical Engineering)