By Neil Nachbar

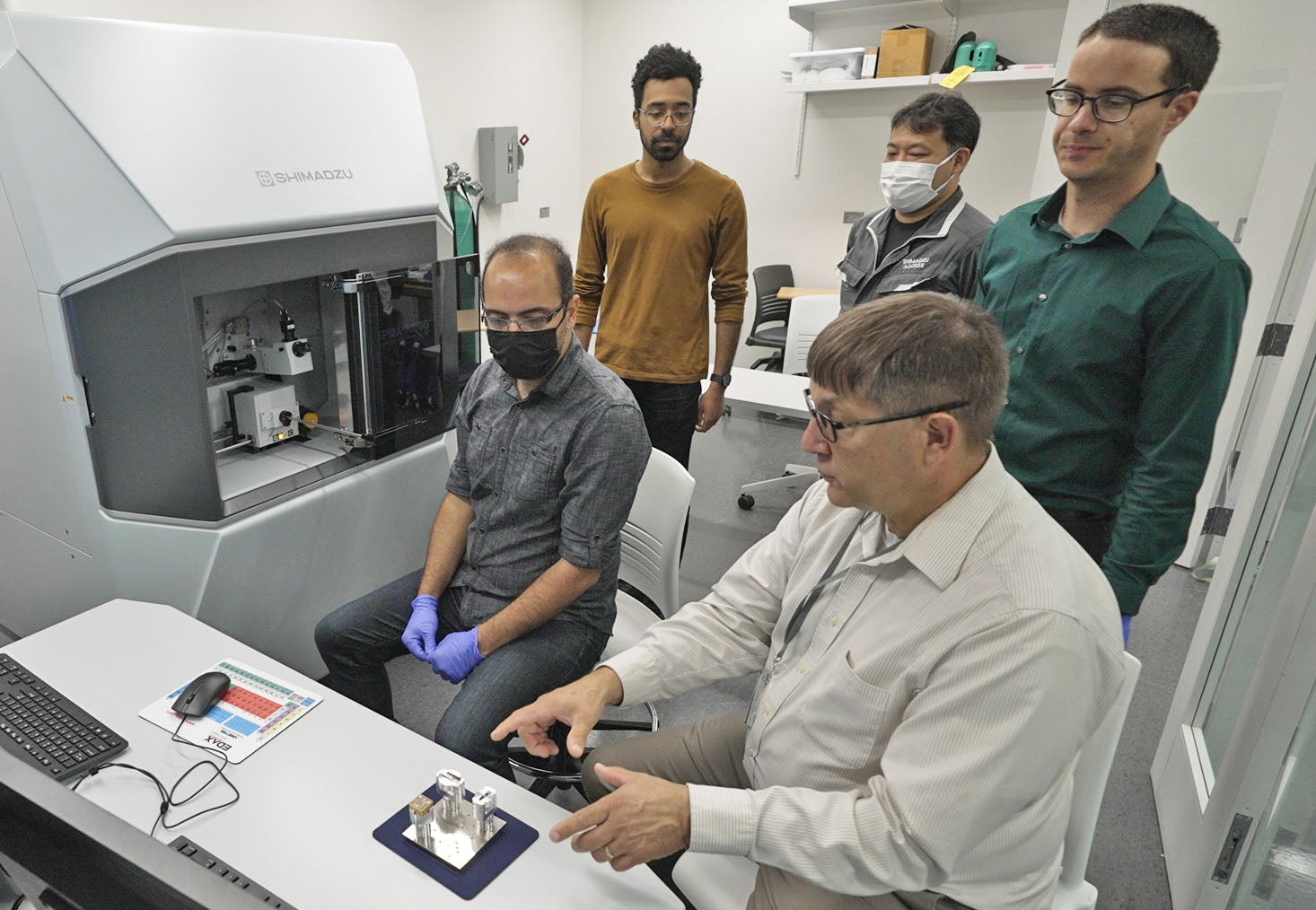

The state-of-the-art equipment in the Shimadzu Engineering Research Core Facility at the University of Rhode Island was already impressive.

The assortment of instruments became more unique and valuable with the addition of a $1.3 million electron probe microanalyzer, the EPMA-8050G. This newest version of the device has been sold and distributed in Japan by Shimadzu, but it is the only one in the United States.

The instrument will not only be available for use by URI researchers, but scientists from industry and other universities will have the opportunity to use it.

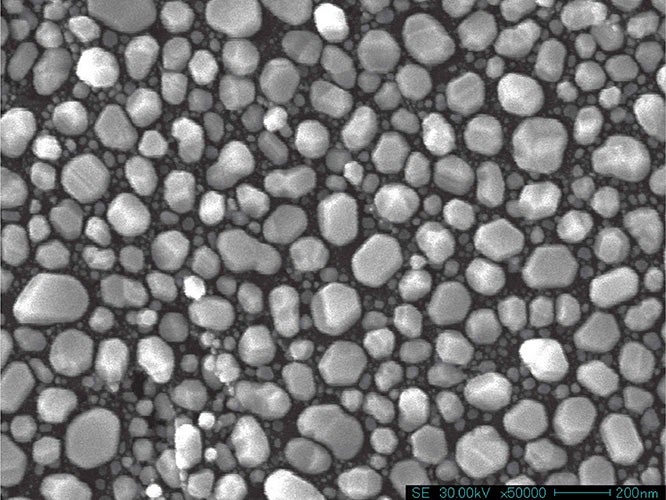

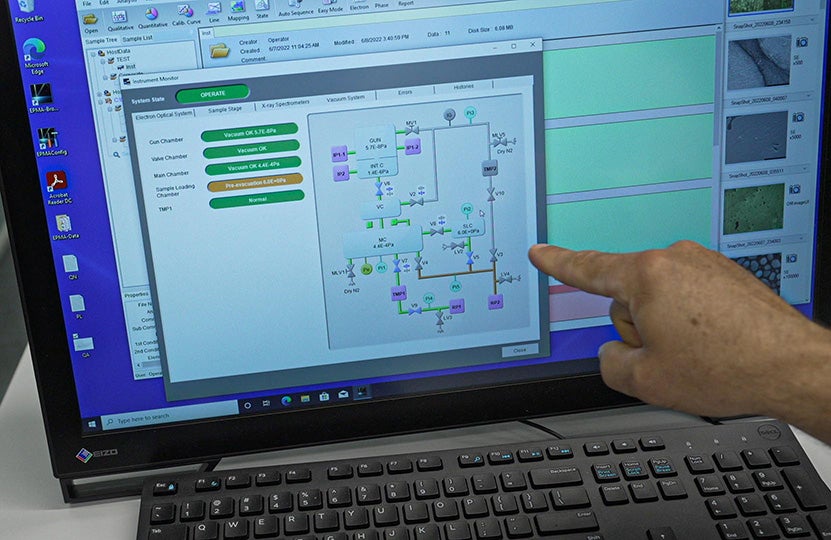

The high-powered microscope works with solids, not liquids or gels, but can analyze at the nanoscale to determine which elements are present in an object, how much of each element, and the space between elements.

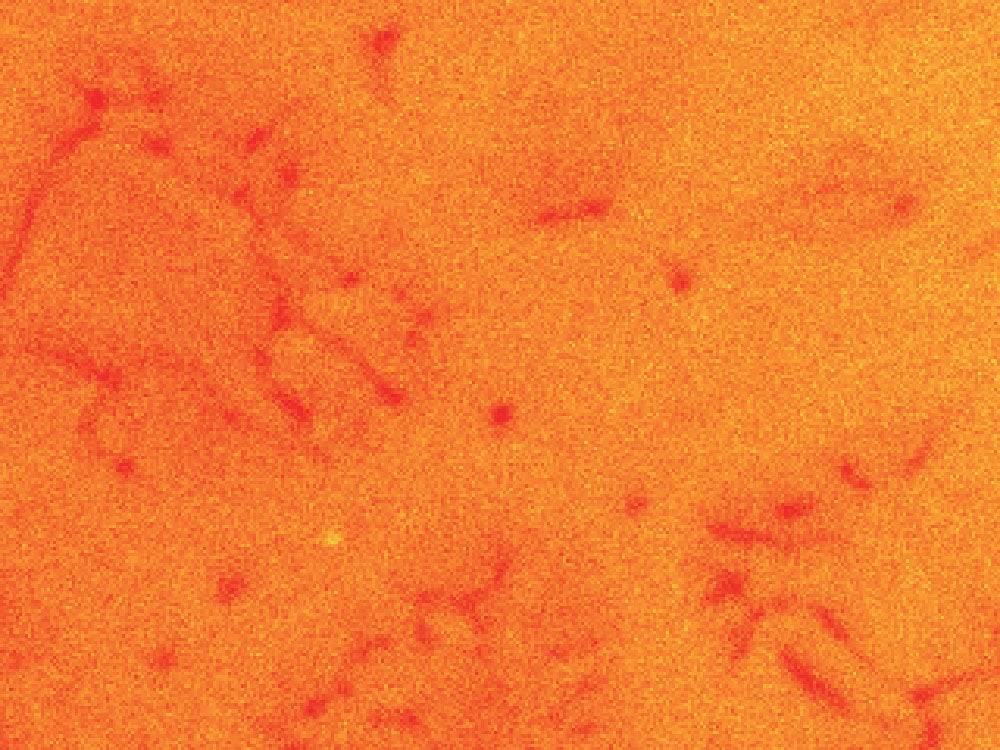

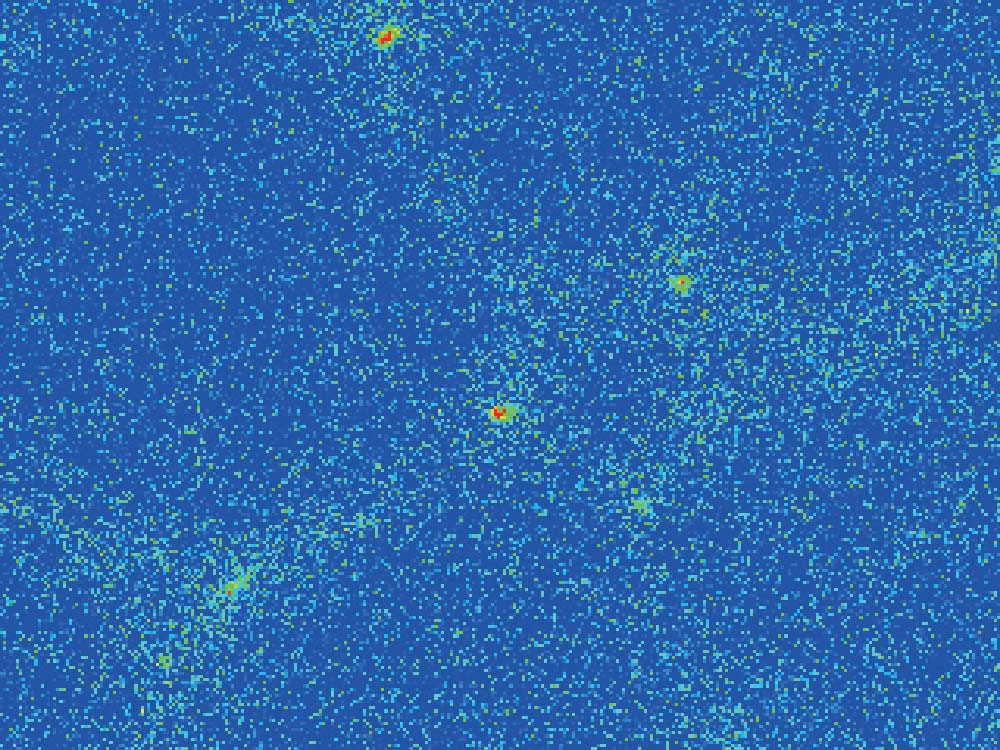

“This machine can non-destructively map individual elements of a solid on a very high spatial resolution so you can determine the spatial distribution of elements in solid objects, such as semiconductor chips, rocks, or solder, for example,” said Joel Langford, product specialist in elemental spectroscopy for Shimadzu.

Langford explained that the machine is versatile because it can be used for a wide range of scientific fields.

“One application is brake pads in automobiles,” said Langford. “You can look at the wear and tear of a brake pad as a function of how much the brake was used and learn how to increase the efficiency of the pad by mapping out its elemental composition.”

Other applications could relate to biology or medicine.

One of the most prolific applications, according to Langford, is in geology.

“There’s an importance in geology of knowing what part of a rock is enriched in one element versus another,” said Langford.

“This instrument is unique in that it is a field emission microscope with wavelength dispersive spectroscopy and energy dispersive spectroscopy,” said Michael Platek, an electrical materials research engineer in the College of Engineering. “Wavelength dispersive spectroscopy is complementary to energy dispersive spectroscopy, but it is superior in identifying elements and quantifying the composition of alloys.”

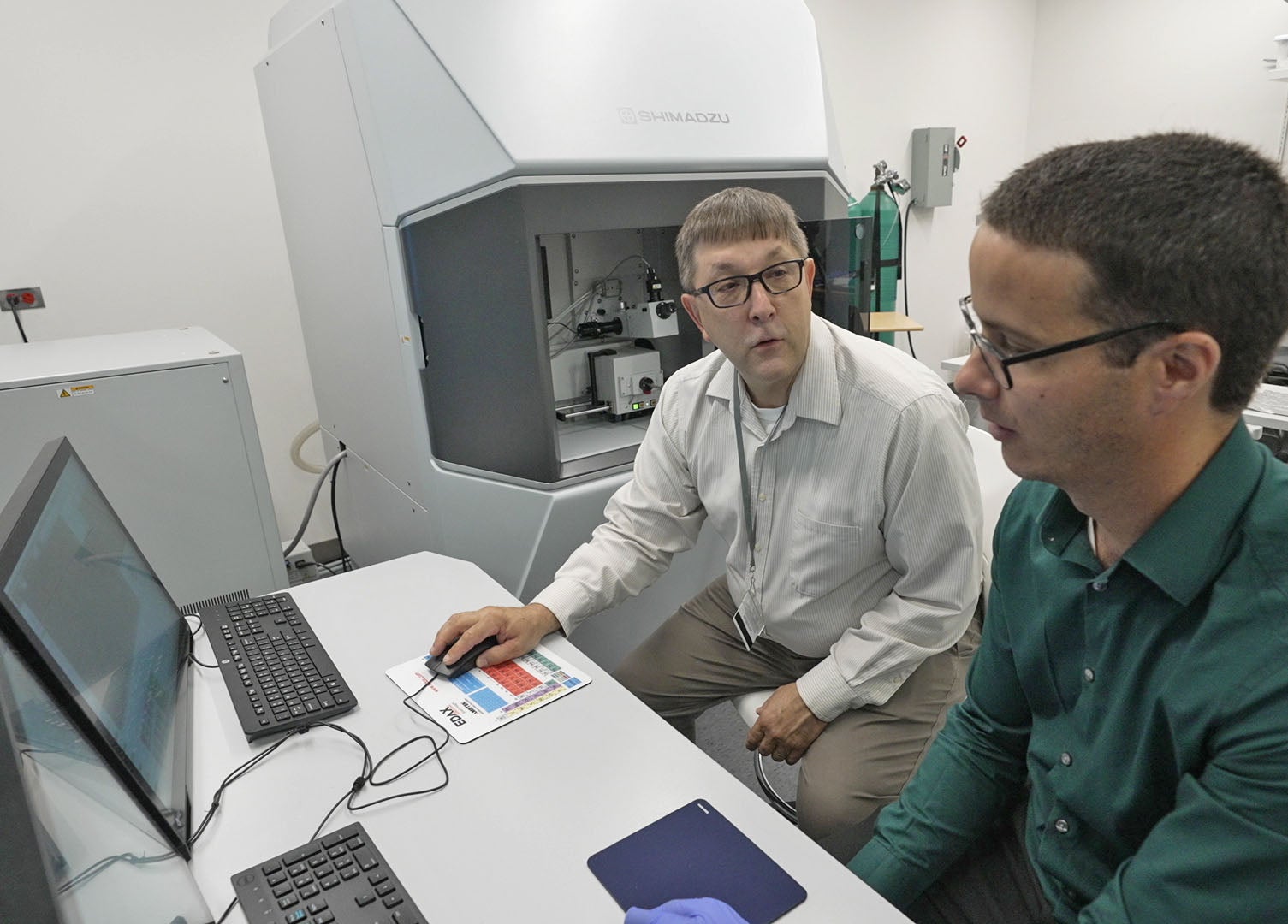

Platek was trained to use the machine by the Shimadzu engineers and will instruct others on how to use it.

“Shimadzu stands firmly behind its equipment,” said Platek. “I look forward to working with their engineers over the next five years of our service agreement, as I try to fully master the instrument.”

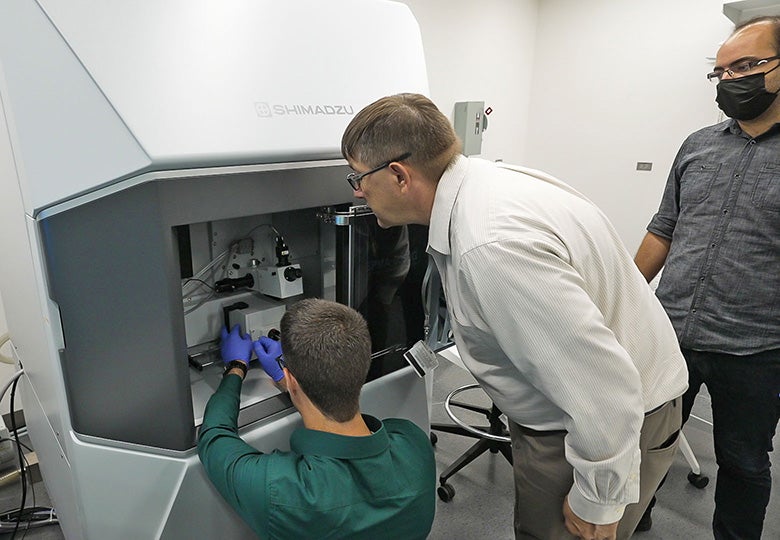

The Shimadzu Engineering Research Core Facility is located on the lower level of the Fascitelli Center for Advanced Engineering. It took two weeks for Shimadzu engineers to install and test the device, and to train URI personnel on how to use it.

Platek received a glimpse of the device’s capabilities during his training when he examined a sample from a local company. The instrument identified the elemental composition of the sample, as well as the quantity and specific location of each element.

Anyone interested in learning more about the electron probe microanalyzer may contact Platek via email or call 401-874-5828.