Grad Student’s Concrete Idea Wins Kudos

Efforts to extend the life of structures and reduce repair costs have led engineers to develop “smart materials” that have self-healing properties, but many of these new materials are difficult to commercialize. A new self-healing concrete developed and tested by a URI graduate student may prove to be cost-effective.

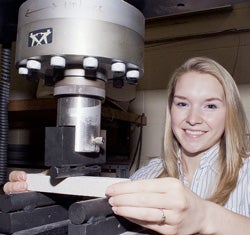

Michelle Pelletier, while a master’s degree candidate, embedded a microencapsulated sodium silicate healing agent directly into a concrete matrix. When tiny stress cracks begin to form in the concrete, the capsules rupture and release the healing agent into the adjacent areas.

The sodium silicate reacts with the calcium hydroxide naturally present in the concrete to form a calcium-silica-hydrate product to heal the cracks and block the pores in the concrete. The chemical reaction creates a gel-like material that hardens in about one week.

“Smart materials usually have an environmental trigger that causes the healing to occur,” explained Pelletier, who collaborated on the project with URI Chemical Engineering Professor Arijit Bose. “What’s special about our material is that it can have a localized and targeted release of the healing agent only in the areas that really need it.”

Pelletier’s efforts have not gone unnoticed. Public Works magazine named Pelletier, who graduated last summer with a master’s in chemical engineering, a 2010 Public Works Trendsetter whose research could extend the life of roads, bridges, foundations, and sidewalks. She was featured in more than two dozen trade publications in the transportation, construction, engineering, and chemical industries this past fall.

Home

Home Browse

Browse Close

Close Events

Events Maps

Maps Email

Email Brightspace

Brightspace eCampus

eCampus