Not Just Child’s Play

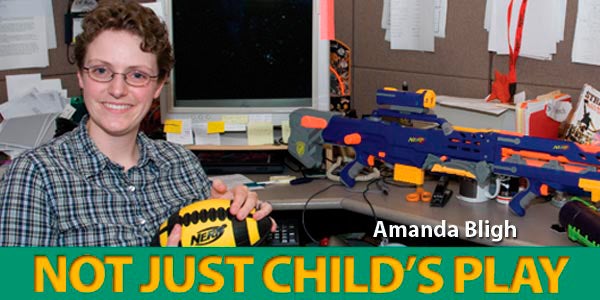

It’s not uncommon for Amanda Bligh to hear electronic voices, see objects fly out of cubicles, or watch co-workers play catch in the hallway

Rather than being a distraction, this somewhat raucous environment is motivating. That’s because Bligh is a product engineer in the Technology Development Group at leading toymaker Hasbro, Inc.

“Hasbro’s culture focuses around toy development, so we generally have products of all types taken apart or sitting around for inspiration,” said Bligh, a graduate student in the URI Department of Industrial and Manufacturing Engineering. “It’s not all fun, of course—Hasbro is a big company and often has an atmosphere like one—but we work the fun in as often as we can.”

As toys have become more and more complex, however, so has the toy design process. Toymakers today need much more than a creative idea that can quickly be turned into a simple product that children can use to entertain themselves. They need engineers who can address structural issues and safety concerns while working within production standards, size constraints, and cost limitations.

A resident of Providence, Bligh works with industrial designers in the United States and manufacturing engineers in China to produce a wide variety of toys and games for children and adults.

“My main role is to support the designers who come up with the ideas,” Bligh said. “They come up with a structure that they want to create, and I select appropriate technologies to help them make it work. We go through lots of options and work with model makers to get to a finished product.”

Much of her work during her four-year Hasbro career has been for the Nerf brand of foam toys. Recent products she has worked on have included the Nerf Longshot Dart Blaster, which launches foam darts up to 35 feet with great accuracy, and Nerf Showtime Hoops, an adjustable indoor basketball unit that can extend to 8 feet and is equipped with a digital scoreboard, audio system, and moving spotlight.

“My role was to help with prototyping and help to make sure that the design idea is feasible,” said Bligh, who was profiled on an episode of the children’s program, Design Squad, which aired earlier this year on public television. “For instance, we were concerned that Showtime Hoops might tip over, so I had to do calculations to see how much weight it could withstand. And we have standards for our darts that address how fast they fly and how wide the impact area is. I had to make sure it was within the standards.”

Bligh said that her favorite toys are those that are especially clever—either something unexpected occurs or they have an elegant solution to a problem. The Nerf Blaster, for instance, has a creative safety system that allows it to fire Nerf darts and nothing else.

“The safety is a valve that is activated by the dart, allowing air out to push the dart, but when other items are in the barrel, the safety isn’t activated, preventing the blaster from firing,” she explained. “Solutions like that are what interests me most in toys and other products.”

Bligh grew up in Contoocook, N.H., but instead of playing indoors with toys, her fondest memories are of riding her bike and exploring the woods and swamps in her neighborhood. She recalls that she always wanted to be an engineer; her father was a mechanic, and she enjoyed watching him take things apart. In high school, she worked for a small company that designed and manufactured amusement park rides, so she had plenty of opportunity to see what engineers do.

Later she majored in mechanical engineering at MIT, where her senior thesis focused on designing a personal electric scooter that gave a smoother ride than typical scooters. “I developed a way to reduce the vibration felt by the user,” she said.

After a year at Hasbro, Bligh began to think about graduate school and ultimately decided on URI’s Industrial and Manufacturing Engineering program.

“I think in terms of mechanisms and materials,” Bligh explained. “There were two components that attracted me to the URI program: Increasing my knowledge of manufacturing processes, and my own research interest in the product development process and how it can be improved and optimized.”

“Amanda started out thinking that she was going to study something to help her company improve the design process, but instead she decided to look at the design process as a whole, regardless of the product,” said Manbir Sodhi, professor of manufacturing engineering and Bligh’s advisor. “She’s interested in what is common in the design process among every product, and also what is different. She has taken a systems engineering approach, and she has done an amazing job.”

Bligh said that in most cases, products are designed and developed using a standard process that doesn’t take into account the unique needs or attributes of individual products. She believes that the development process could be more efficient and effective if a particular attribute—like development schedules, intellectual property issues, product quality, or specific needs of customers—was taken as the focus for the process.

“I’m trying to create a method for focusing the development process on product attributes that are currently given no specific importance but are necessary for the product’s success in a given company,” she explained. “Ultimately, the process should work for all kinds of products.”

While her current job at Hasbro is more focused on products than process, Bligh would be thrilled if some of her ideas for improving the development process were eventually implemented at Hasbro.

When Bligh completes her master’s degree later this summer, she is considering pursuing a doctorate as well. “The research I’m doing is extremely interesting and compelling,” she said. “Maybe it will be a launching point for something else. Eventually I’d like to be in a position of doing consulting work based on the product development process. Or maybe I’ll end up teaching at the college level.”

By Todd McLeish

Home

Home Browse

Browse Close

Close Events

Events Maps

Maps Email

Email Brightspace

Brightspace eCampus

eCampus