A collaboration between research and industry receives Phase 2 funding from the National Science Foundation to develop biodegradable oceangoing bioplastics

October 6, 2022

Plastic’s cheapness, versatility and durability are undeniable, but in a burgeoning Ocean Internet of Things, plastic as we know it and the marine environment are a toxic combination.

“Just as there has been an explosion of networked devices in our daily lives, we’ve seen a big increase in the number of networked devices throughout the ocean,” said URI oceanographer Melissa Omand.

These sensors, nodes in a growing networked “blue economy,” are used to gather and transmit data important to the various industries that do their work in the marine environment, such as shipping, tourism, oil and gas, and fisheries. Once deployed, these devices are never retrieved, adding to the growing amount of plastic in the sea.

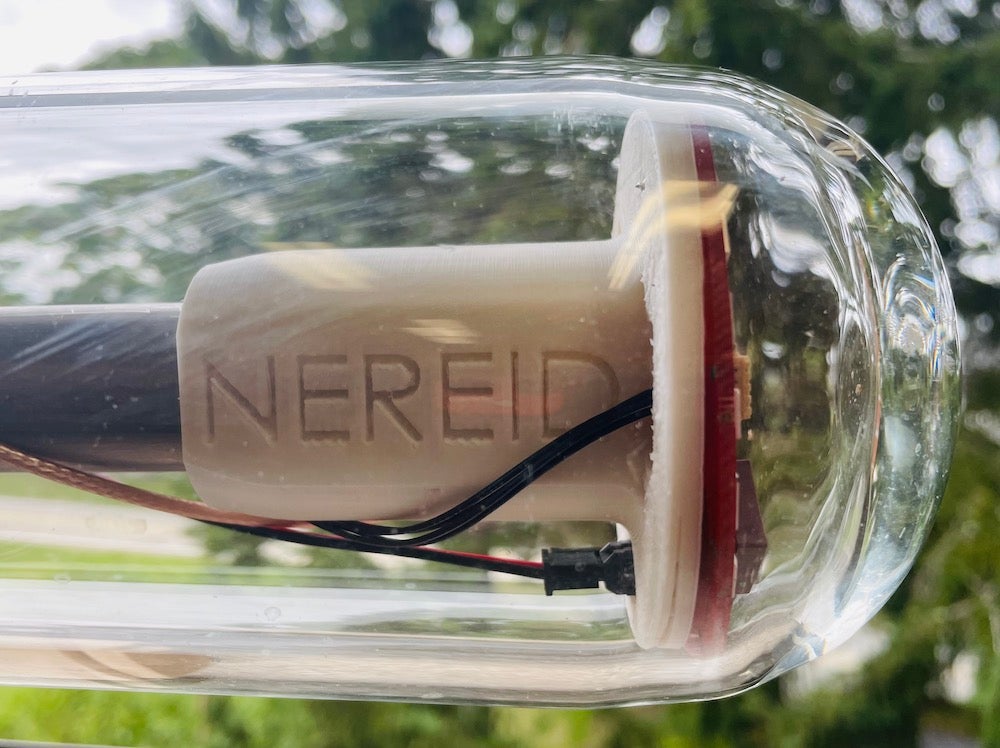

But what if there was a way to avoid the problem of plastic pollution while still reaping the benefits of a networked ocean? This potential win-win has inspired Omand, along with her team-lead, UC Santa Barbara marine microbiologist Alyson Santoro, University of Rochester synthetic biologist Anne Meyer, ecologist Ryan Freedman from the Channel Islands National Marine Sanctuary and industry partner Mango Materials. Together, they are developing bioplastics, engineered to degrade in the ocean. Supported by the National Science Foundation’s Convergence Accelerator program, the group, collectively known as Nereid Biomaterials, is poised to dive into Phase 2 of their research project, in which their biodegradable bioplastic is put to the test.

“I’m really excited to put our lab’s basic research on marine microbiology into an applied problem,” Santoro said. “But more than anything, I’m just excited I get to keep working with such a fantastic group of people.”

The base material for this technology is the biopolymer polyhydroxybutyrate (PHB), a natural polyester harvested from carbon-assimilating bacteria. Methane, a potent greenhouse gas, is the carbon compound of choice to feed these microbes.

“Mango Materials grows these bacteria on methane that is emitted by wastewater treatment plants,” Santoro said, “which is another win.”

Because these bacteria have been making this polymer for billions of years, she added, naturally other microbes have figured out how to break it down for energy. This is where Santoro and her lab’s expertise comes in.

“We’re culturing new bacteria that can break down these polymers,” she said. One focus of their work is the isolation of bacteria that thrive in the cold conditions of the ocean, an important factor to consider as most biodegradable plastics can only decompose in high-heat composting facilities.

Developing this strategy was part of Phase 1 of the project, in which the team also gathered input and built a prototype, created with Omand’s oceanographic sensor design expertise.

“There was evidence suggesting it was impossible to make Mango’s PHB into 3D printer filament, but we tried it anyway,” said Omand. “To our surprise, we were able to quickly start up filament production, which allowed me to experiment with different shapes and infills. Our goal is to develop a dual-head printer that can print marine bacteria and PHB in tandem.”

“We did dozens of interviews with potential end-users of biodegradable plastics, and found out what their material needs were,” Santoro said. The team also spoke with regulators and nonprofits dedicated to dealing with marine debris. These discussions informed their research directions and inspired user-friendly innovations.

“We found that there’s a huge need for biodegradable materials and there are a range of lifespans that users require for their items,” she continued. Some wanted a material that could disappear in a day, while others wanted devices that would last a year. Yet others they spoke to wanted to be able to trigger the degradation.

Phase 2, according to Santoro, involves using the bioplastic in the real world. In collaboration with more than a dozen industry partners who have committed to using this new technology, the project team will see how well their bioplastic performs under different ocean conditions as well as how the material breaks down.

Phase 2 is also where the team refines their product’s functionality with the use of technology that Meyer developed: a 3D printer for live bacterial cells that can be used to embed or apply PHB-eating bacteria to the biopolymer. Strategic placement of these bacteria in or on the plastic can provide users with options for when and how quickly the biopolymer degrades.

Additionally, the team will participate in the NSF Convergence Accelerator’s innovation and entrepreneurial curriculum, that includes training on product development, intellectual property, financial resources, sustainability planning and communications and outreach. The end goal is to ensure the solution is sustainable beyond NSF support and provides a positive societal and economic impact.

Simultaneously, in partnership with the UCSB Center for Science and Engineering Partnerships, (CSEP) the group plans to roll out an academic-industry internship program to mentor undergraduates and train the next generation of microbiologists, materials scientists and ocean engineers.

It’s still early, but if all goes well, Santoro said, it might be time to bring their ocean bioplastic to the wider world and to shift how oceangoing plastics are made.

“One potential avenue is commercialization,” she said, “but we’re exploring lots of options.”